Bill Gabbard

Brand new dies, once-fired brass, and a new caliber that most people haven’t heard of yet - it doesn't get much better than that! While working on the article testing the Savage 110 Ultralight in 7mm PRC, I noticed that I couldn’t find any information about loading for the new caliber. A couple of quick e-mails to Seth Swerczek of Hornady and Robin Sharpless of Redding and I had dies on the way. Hornady’s website had loading data and Geoff Esterline of Capstone Precision supplied me with data that the folks from Berger and VihtaVuori had been working on. By the time I got started Hodgdon had load data on their online data center. Armed with information and quality 7mm bullets from Hornady and Berger, I headed to the loading bench like a baby with a new toy!

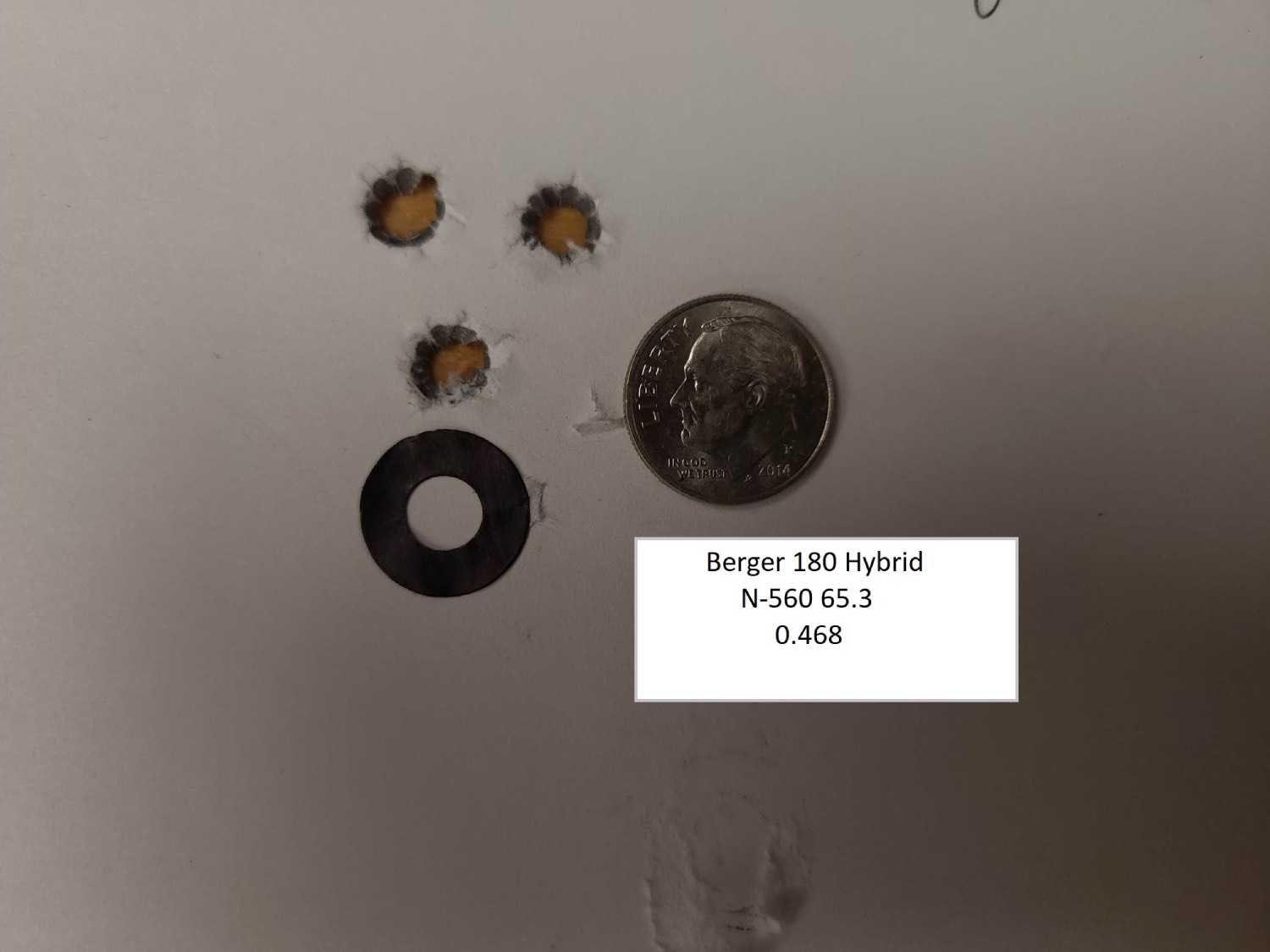

Berger's Hybrid 180 gr

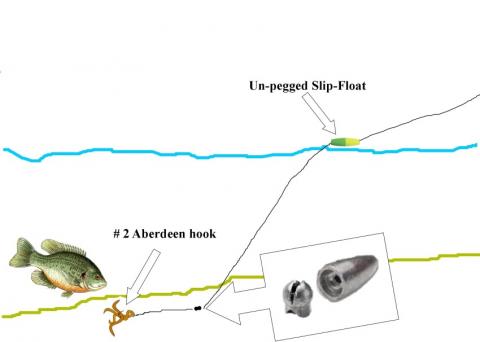

First up, I built loads with Berger’s Hybrid 180 gr bullet using eight kinds of powder. My results caused a little head scratching! Three of the loads produced groups under one inch but all eight groups had one thing in common - two good shots and a flyer. This often indicates one of three things: either parallax issue with the scope; a primer not liking a particular powder; or a bullet length seating issue. I felt confident in the parallax setting on the Leupold VX-5 and pretty well ruled out the primers since I had the same issue with eight different powders. I had seated the bullets using the limited amount of data available for the brand-new round, so I measured the overall length of the Hornady factory ammo as well as the length to the ogive. Turns out the factory ammo was from 0.025 inch to 0.060 inch longer than the loads that I had built using the available load data. Carefully measuring the factory ammo and testing for magazine fit and ease of chambering, I built 5 more sets of loads using VihtaVuori 560 that had done the best previously, using different seating depts closer to the factory loads. My next trip to the range confirmed that it was a simple bullet seating issue. All five groups were under an inch. My best was a nice triangle well under one-half inch using a seating length that was 0.070 off the lands and functioned flawlessly.

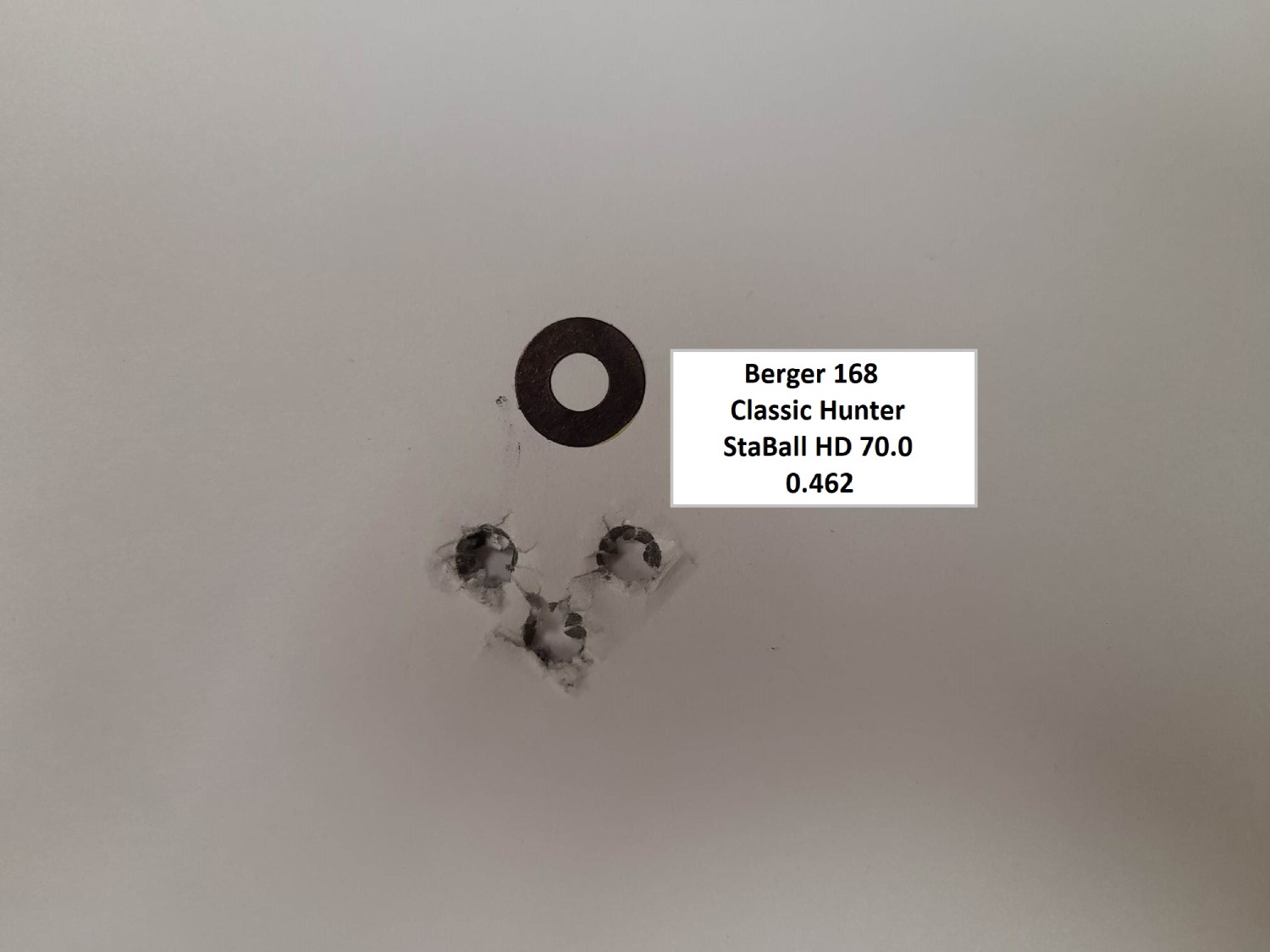

Berger's 168 gr Classic Hunter

Next up, I used Bergers 168 gr Classic Hunter that had done so well in a recent loading article for 7mm Rem Mag. The Classic Hunter did not disappoint. I used four different powders with a seating depth close to what had worked with the 180-gr bullet. One group was barely over one inch at 1.010, and the three others were all under one inch. Hodgdon’s new Winchester StaBall HD produced the best group of just under one-half inch almost identical to the load with 180 gr bullets.

Hornady 162 gr

Third round of loading for the 7mm PRC, I tried a pair of 162 grain bullets from Hornady. The 162 gr ELD-X and the time tested 162 SST. I loaded three shot groups of each bullet with VihtaVuori N-560, Alliant RL22, StaBall HD, and IMR 4831. I tried the same strategy for seating depth that had worked for the 180 and 168 gr bullets and had mixed results. While the N-560 produced a group under one-half inch and four of the groups were under one inch, five of the eight showed the same tendency that I encountered earlier - two bullet holes touching or in one hole with a flyer. Under half inch is probably good enough to move on, but the fact that three of the four loads with the 162 ELDX bullets had two in one with a flyer forces me to try at least one more set of loads to lose the flyer! There is a good possibility that it was shooter error, but I had to give it one more try. I loaded enough ammo for three more three shot groups with the 162 ELD-X bullet and enlisted the aid of local competitive shooter Richard “Casey” Sandlin to help with the shooting duties trying to eliminate the shooter being the weak link in the chain. Casey’s groups almost mirrored mine, so I decided that under one-half inch was good enough for these bullets with a bone stock rifle and hunting bullets.

Hornady 154 gr ELD-X

The last bullet I tried was Hornady’s 154 ELD-X. This bullet has been consistently good for me in a variety of 7mm rounds over the years and it didn’t fail me this time. While it didn’t break the one-half inch mark, three of the four loads I tried were under one inch with the fourth group barely over at 1.091.

Best Groups

|

Bullet |

Primer |

Powder |

Charge |

Group |

|

Berger 180 Hybrid |

CCI 250 |

N-560 |

65.3 |

0.468 |

|

Berger 168 Classic Hunter |

CCI 250 |

StaBall HD |

70.0 |

0.462 |

|

Hornady 162 ELD-X |

CCI 250 |

N-560 |

67.2 |

0.448 |

|

Hornady 162 SST |

CCI 250 |

StaBall HD |

70.5 |

0.806 |

|

Hornady 154 SST |

CCI 250 |

RL-22 |

67.0 |

0.793 |

Working with a new caliber is always interesting and the 7mm PRC was no exception. This new round is destined to be compared to the old favorite 7mm Rem Mag at every turn. The biggest advantage I see at this point is ease of obtaining accuracy with handloads. While I haven’t spent the time to get groups under a quarter inch that I have with some of the 7mm Rem Mag rifles that I have worked with, all five of the bullets that I worked with easily produced groups of less than one inch their first trip out. Three of the five went under one-half inch with minimal effort. The 7mm PRC was designed with accuracy in mind. The lack of belt allowing the round to headspace on the shoulder, and rifles with twist rates for heavy bullets help insure this. Long brass life is probably going to be another benefit. All the brass I used was from firing Hornady factory ammo for the Savage 110 Ultralight 7mm PRC article. Some of this brass was fired as many as 6 times, and still did not need trimmed. Long brass life, easy to obtain accuracy, and likes a variety of bullet weights - nice combination for a reloader!