Mike Tapley of Taproot Knives | Originally published in GameKeepers: Farming for Wildlife Magazine

adhered to a flat surface and a piece of leather strap for

final touch up.

I vividly recall trips to the local feed or hardware store when I was just a young boy. If I was lucky, a local farmer-neighbor would be standing at the front counter running the blade of his pocketknife over the large whetstone attached to the countertop near the cash register. If I was real lucky, the owner would let me hold the knife.

Some 50 years later, I am still fascinated with knives and I have made patterns designed for cutting chores ranging from shucking oysters, personal protection and everything in between. It’s remarkable how many customers remark they have no knife sharpening skills. If you count yourself among this number — there is hope. Whether you carry a commercially crafted knife or a custom made blade, you can maintain an effective cutting edge with a few useful knife sharpening tips. You can put a razor-edge on your knife — assuming it is made of good steel and properly heat treated.

Rule No. 1 of Knife Sharpening: Ditch the Low-Quality Knives

Many knives are not and will never take and hold a good cutting edge. Throw them away. Always invest in trusted knife brands. If you can, research the steel hardness, which is measured by “Rockwell” standards — a test performed on blades to determine hardness after the blade is heat treated and tempered. A number of 55 to 60 is an excellent range for knife sharpening and holding an edge. Knowing that you have fences to repair, plots to plant and trail cameras to check, let’s get on with the sharpening.

How to Sharpen a Knife

on the sharpening medium. Tilt the knife to follow the angle

of the edge-grind and pull the knife toward you applying

consistent pressure from the back of the edge through the

point.

Before you begin, study your blade’s edge geometry. Custom or bench made, it’s a “v” and the “point” of the “V” is where the cutting takes place. The sides of the “V” are the part of the edge that needs consistent contact with the sharpening medium to renew the cutting edge.

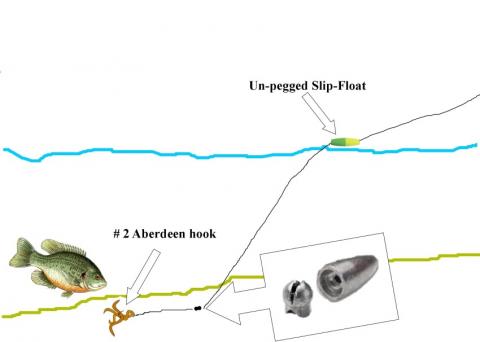

Next, select your knife sharpening device. /our-obsession/blogs/press-releases/mossy-oakr-and-smithsr-partner-to-offer-sharpeners-for-knives Quality Arkansas honing stones in medium and fine grit are excellent. Flat diamond hones are good and easier to work with than round-configured diamond or steel sharpeners. I suggest that you try the sandpaper method.

My choice is #220 grit wet/dry sandpaper and a piece of leather strap for final touch up. Attach the sandpaper to a perfectly flat surface such as a scrap of marble or piece of wood. Use spray adhesive or masking tape to secure the sandpaper to the flat backing.

The technique is the same whether you are using a stone, diamond hone or the sandpaper. Grip the knife by the handle and turn the knife edge away from you. With the edge facing away from you lay it on the sharpening medium. Tilt the knife to follow the angle of the edge-grind and pull the knife toward you applying consistent pressure from the back of the edge through the point. At the end of the pull, pick up the knife and repeat another pull. Check the shine that appears on the edge to make sure the edge-angle “V” is duplicated.

Repeat this for five to ten pulls, and then turn the knife over with the edge facing you. Contact the sharpening medium and push the knife away from you using the same number of strokes. Remember to “pull” the left edge toward you and “push” the right side away from you – do not go back and forth.

Apply the same number of passes over each side of the knife. You will know you have finished when you see a light, fine-feathered line on the edge from back to tip.

Finish the process with the same “push-pull” process against the leather. Tip: Take a wide belt, stand on the end to tighten and push and pull. I use a strip of leather mounted to a piece of plywood. I coat the leather with green buffing compound readily available at most hardware stores.

This process takes time and patience, but will produce a hair shaving edge if you persist. You can maintain the edge between cutting chores with the leather without visiting the stone or sandpaper.

If you have a knife with edge nicks or chips, more drastic measures are required. Contact your local custom maker or cutlery shop, or feel free to give me a call. DO NOT attempt to file or grind your knife on a regular grinder. You most likely will ruin the temper and render the blade useless.

and push the knife away from you using the same number

of strokes. Remember to “pull” the left edge toward you and

“push” the right side away from you – do not go back and

forth.

TIP: Some knives are made of steel that just will not sharpen. Time to upgrade with a better brand or a custom knife made to your specifications.

Readers of GameKeepers live a unique lifestyle and depend on knives for a variety of chores. A good, sharp knife is a necessity and a “faithful companion.” And, in fact, a sharp knife is safer to use, whether you are whittling a peg for a ground blind, cutting hay bale strings or field dressing a critter.

About the Author

Mike Tapley, aka TapRoot, divides his time in managing two tracts of timberland for aesthetics and wildlife, spending time with eight grandchildren, bowhunting, knife making and recently —carving bowls with hand adzes. He made his first knife in 1975. His craft focuses on custom fixed-blade hunters, specialty knives, fillet knives and kitchen cutlery. Each knife is made to the specifications of the customer or from his designs. He completes each process in the building process from design to heat treating. If you have questions about your knives or want to order a one-of-kind custom knife, call or email TapRoot Knives: (334) 567-7328; mike@taprootknives.com.